- Tear-off is bound to occur

- It is absolutely unsuitable for exacting hygiene demands

- Difficult to clean

- Costly to repair

- Never a permanent solution

What makes our products so special?

Why PRO-FIL

Flat skirting strips are the wrong solution wherever hygiene is of the essence.

Given the high demands on hygiene in health care institutions, flat skirting strip solutions – which are often mistakenly chosen as more cost-advantageous – are always the wrong solution.

What’s more the all-essential cleaning standard can never be guaranteed with a flat skirting strip and its dirt trap crack in the area where wall and floor meet. The material is simply predestined to tear away and leave a dirt collecting gap. This is why a flat skirting strip solution is not the choice for a real and hygienic permanent solution; these are quite simply not economic, efficient or ecologically sustainable.

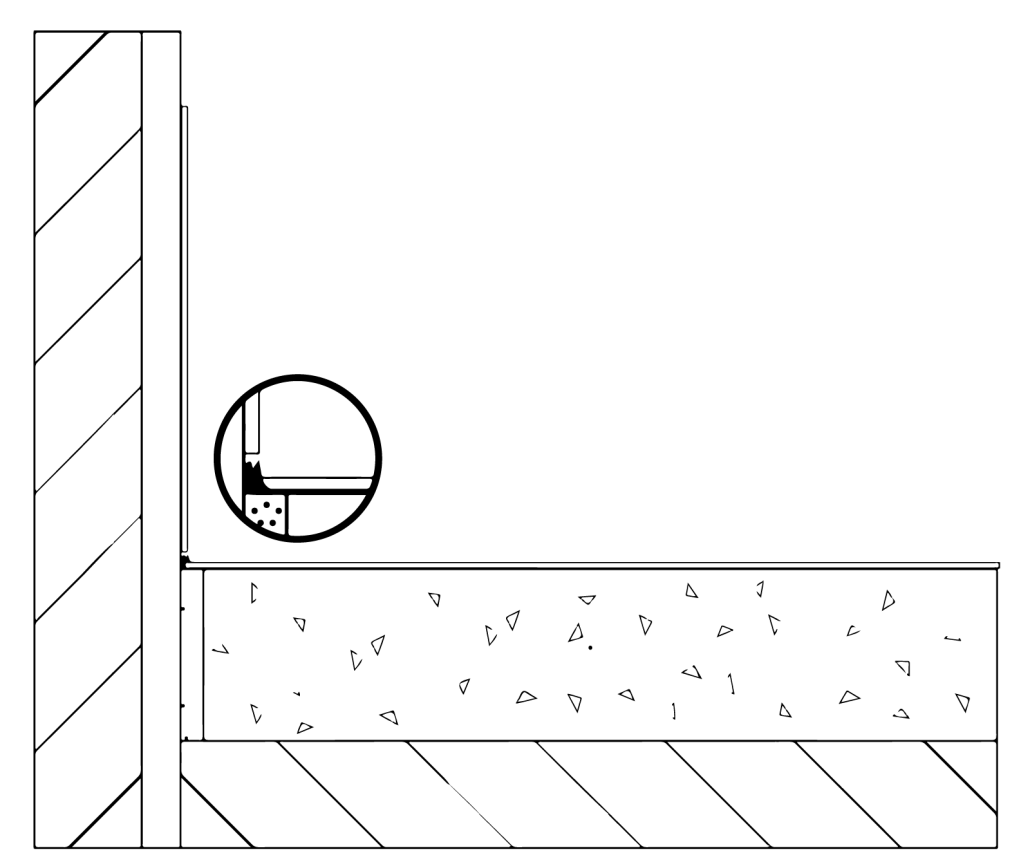

Experience has shown that damage caused by the sagging of the screed floor normally only occurs after construction has been completed. At that time, the buildings are normally already in operation and repair of the damage on a building “in use” is always very complex.

Not a permanent solution

Floor covering

Tear-off due to sagging of screed floor

Silicone

Floor covering

Rigid concave strip reinforcement.

This design has many drawbacks, because the outline of the aluminium profile can be seen through the floor covering; the resulting dirt-collecting edge is a problem not only for visual but also for hygienic reasons.

Because of the aluminium material, cutting is only possible with a mitre saw. What’s more the cove cannot mirror any sagging of the screed because the reinforcement is rigid. Depending on the type of load, the radius is much bigger than for elastic reinforced concave moulding strips.

- Rigid reinforcement cannot compensate for movement

- Difficult to handle – mitre saw needed for cutting

- Short lengths

- Edge of aluminium section visible

- Reinforcement does not level off

- Connection, e.g. to door frames, is very difficult

PRO-FIL cove

Reinforcement levels off to zero

Aluminium reinforcement

Because of its thickness, aluminium is visible through the floor covering.

Flash cove installation in one piece

Laying a floor covering in trough shape requires a very high level of expertise. “Surgical precision” is needed to make the cuts exactly and avoid mistakes of the kind shown in these pictures.

In addition to lots of cutting waste (ecological aspect), a thoughtless cut can only be repaired with great amounts of silicone or other sealants. This is the reason why many corners and connecting joints are not of the expected quality. Lasting repair is always connected with high costs.

- More cutting waste

- Skilled craftsmanship required

- Wrong cuts difficult to repair

- Cavities between sub-profile and floor

- Outer corners difficult to design

- Risk of cracking with many floors

Traditional formation of corners

With corners built the standard way, the corners are normally closed by bonding or grouting, and due to shrinkage of the material there is frequent tear-off.

Often slight contact (e.g. with a cleaning machine) may be sufficient to tear off the covering from the wall.

- More cutting waste

- Skilled craftsmanship required

- Wrong cuts difficult to repair

- Cavities between sub-profile and floor

- Outer corners difficult to design

- Risk of cracking with many floors

We offer an alternative solution. Therefore PRO-FIL.

PVC & rubber tiles

The main advantages of industrial pre-fabrication of wall coves made from floor covering tiles are the consistently small radius and the high quality of joining the tiles (thermal bonding on the back).

The thermal bonding of the tiles is done at the factory in such a way that the joints between the individual tiles are hardly visible.

The process also ensures tightness of joints. Such high quality is impossible to achieve for floorers when creating the coves on site by hand.

LVT Design Vinyl

LVT Design Vinyl of various sizes and materials are processed into cove rods of the desired dimensions. (Minimum width of boards: 152 mm). The main advantage of industrial pre-fabrication of wall coves made from boards is the consistently small radius. Such high quality is impossible to achieve for floorers when creating the coves on site by hand.

PVC, rubber & linoleum

Installing a PRO-FIL cove is easy. All you need for cutting is a conventional utility knife that is always at hand. Installation time is short thanks to the length of the rods (up to 240 cm).

Hygienic all around and easy to lay. High-quality thanks to mechanical prefabrication.